Model No.︰Cemedine sx1010

Brand Name︰CEMEDINE

Country of Origin︰Japan

Unit Price︰US $ 80 / pc

Minimum Order︰10 pc

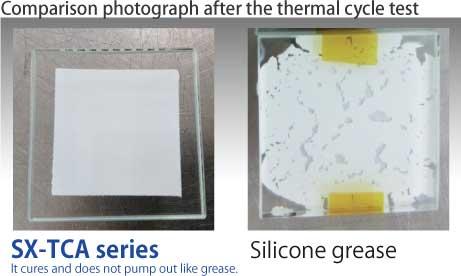

Elastic adhesive | Thermal Conductive Elastic Adhesive SX-TCA series

Features

No concern for pump out (compared to grease)

Product data

Adhesive properties for various types of adherends

(Tensile shear strength :MPa)

| Adherends | SX1008 | SX1010 | RH96L | |||

|---|---|---|---|---|---|---|

| Adhesive strength | Failure Modes | Adhesive strength | Failure Modes | Adhesive strength | Failure Modes | |

| Hard polyvinyl chloride | 2.18 | CF | 1.61 | CF | 0.68 | CF1AF9 |

| Polycarbonate | 2.16 | CF | 0.77 | AF | 0.82 | CF2AF8 |

| Polystyrene | 1.98 | CF | 1.24 | AF | 0.61 | AF |

| ABS | 2.10 | CF | 1.24 | CF5AF5 | 0.61 | AF |

| Acryl | 2.20 | CF | 1.60 | CF | 0.28 | AF |

| Nylon 6 | 1.66 | CF | 1.28 | CF | 0.65 | CF1AF9 |

| Steel plate | 2.23 | CF | 1.50 | CF | 0.55 | AF7,Uncured3 |

| Aluminum | 2.85 | CF | 1.90 | CF | 0.76 | AF |

* CF:Cohesion Failure, AF:Adhesive Failure

The numbers indicate their proportion to the adhesion area.

Surface treatment: Steel plate is MEK degreased, Plastic is IPA degreased

Coating quantity: Coated on both sides 100μm thick (per side)

Open time: SX1008, SX1010 No open-time, RH96L 2 minutes

Curing: 23°C 50%RH x 7 days

Tension speed: 50mm/min

Heat aging resistance(SX1008/SX1010)

(MPa)

| SX1008 | SX1010 | |||||||

|---|---|---|---|---|---|---|---|---|

| 120°C | 130°C | 120°C | 130°C | |||||

| Initial value | 2.85 | CF | 2.85 | CF | 1.90 | CF | 1.90 | CF |

| 1W | 4.69 | CF | 4.82 | CF | 3.67 | CF | 3.88 | CF |

| 2W | 4.60 | CF | 4.10 | CF | 4.04 | CF | 3.81 | CF |

| 4W | 4.53 | CF | 3.98 | CF | 3.84 | CF | 3.70 | CF |

| 8W | 4.16 | CF | 3.01 | CF | 3.72 | CF | 3.20 | CF |

| 12W | 4.12 | CF | 2.48 | CF | 3.68 | CF | 2.96 | CF |

| 18W | 2.89 | CF | 1.99 | CF | 2.84 | CF | 2.54 | CF |

* CF:Cohesion Failure

Adherends: Aluminum (alumite)

Test method : JIS K6833

Heat aging resistance(RH96L)

(MPa)

| 150°C | ||

|---|---|---|

| Adhesive strength | Failure Modes | |

| Initial value | 0.76 | AF |

| 100h | 0.89 | CF |

| 300h | 1.00 | CF |

| 500h | 1.19 | CF |

| 1000h | 1.52 | CF |

| 2000h | 2.22 | CF |

| 3000h | 2.58 | CF |

* CF:Cohesion Failure, AF:Adhesive Failure

Adherends: Aluminum (alumite)

Test method : JIS K6833

High-temperature and high-humidity test

(MPa)

| 85°C x 85%RH | SX1010 | |

|---|---|---|

| Adhesive strength | Failure Modes | |

| Initial value | 1.90 | CF |

| 1W | 3.14 | CF |

| 2W | 3.23 | CF |

| 4W | 3.16 | CF |

| 8W | 3.43 | CF |

| 12W | 3.51 | CF |

| 18W | 3.67 | CF |

* CF:Cohesion Failure

Adherends: Aluminum (alumite)

Test method : JIS K6833

Thermal shock test

(MPa)

| RH96L | ||||

|---|---|---|---|---|

| Adhesive strength | Failure Modes | Thermal conductivity | ||

| Initial value | 0.76 | AF | 2.14 W/m・K | |

| -40°C

↑↓ 125°C |

100 cycles | 1.28 | CF1AF9 | 2.04 W/m・K |

| 300 cycles | 1.46 | CF1AF9 | 2.15 W/m・K | |

| 500 cycles | 1.75 | AF | 2.06 W/m・K | |

| 1000 cycles | 2.04 | CF5AF5 | 2.71 W/m・K | |

| 2000 cycles | 2.59 | CF7AF3 | 2.82 W/m・K | |

| 3000 cycles | 3.02 | CF9AF1 | 2.81 W/m・K | |

* CF:Cohesion Failure, AF:Adhesive Failure

The numbers indicate their proportion to the adhesion area.

Adherends: Aluminum (alumite)

Test method : JIS K6833

Property

| Thermal Conductive Elastic Adhesive | |||||

|---|---|---|---|---|---|

| SX1008 | SX1010 | RH96L | |||

| Application / Properties / Features | RoHS compliant

UL94 V-0 Equivalent |

||||

| Low viscosity | High viscosity | Heat resistance | |||

| Type | One-Component Type Elastic Adhesive | ||||

| Base | Special acrylic-modified polymer | ||||

| Appearance | White paste | White paste | Gray paste | ||

| Viscosity | Pa・s/23°C | 120 | 650 | 250 | |

| SVI | 2.0 | 4.2 | 4.5 | ||

| Density | g/cm3 | 1.98 | 2.00 | 2.15 | |

| Skin over time | 23°C | 3min | 3min | 7min | |

| Cured properties | Hardness | Shore A | 84 | 85 | 65 |

| Glass transfer point | °C | -62 | -62 | -44 | |

| Breaking strength | MPa | 2.5 | 1.8 | 1.1 | |

| Elongation at break | % | 30 | 20 | 45 | |

| Thermal conductivity | W/m・K | 1.7 | 2.1 | 2.14 | |

| Linear expansion coefficient | ppm/K | 77 | 55 | ||

| Electric Characteristics | Volume resistivity | Ω・cm | 6.6 x 1012 | 1.3 x 1013 | 4.1 x 1011 |

| Dielectric constant | 1MHz | 0.64 | 3.1 | 7.7 | |

| Dielectric loss tangent | 1MHz | 0.01 | 0.12 | 0.46 | |

| Insulation breakdown voltage | kV/mm | 38 | 22 | ||

| Capacity | 135ml | 333ml

*Made to order |

333ml

*Made to order |

||

| 333ml | |||||

Viscosity: BS-type rotational viscometer (Rotor No. 7, 10 rpm)

SVI: Viscosity ratio between 10 rpm and 1 rpm

Density: Based on the specific gravity cup method in JIS K6833

Thermal conductivity: Compliant with JIS A1412

Volume resistivity: Compliant with JIS K6911 (measurement voltage: 500 V)

Dielectric constant: Compliant with JIS K6911 5.14

Dielectric loss tangent: Compliant with JIS K6911 5.14

Insulation breakdown strength: Increase the voltage until insulation breakdown occurs, and measure the voltage limit

Price Terms︰ FOB HONGKONG, FOB SHENZHEN

Payment Terms︰ TT