Model No.︰PHOTOBOND 150

Brand Name︰Surise MSI

Country of Origin︰-

Unit Price︰-

Minimum Order︰-

Ultraviolet cure adhesives PHOTOBOND

|

PHOTOBOND is adhesive that cures with exposure to ultraviolet light. We were the first to put it to the practical use.

|

| PHOTOBOND is adhesive that cures with exposure to ultraviolet light. We were the first to put it to the practical use.

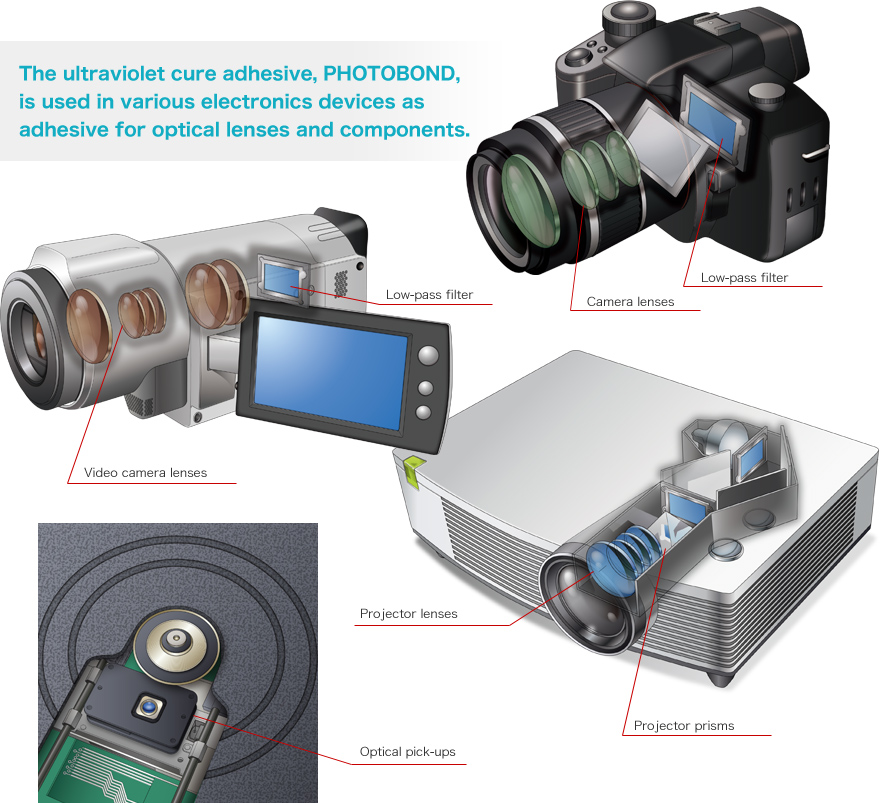

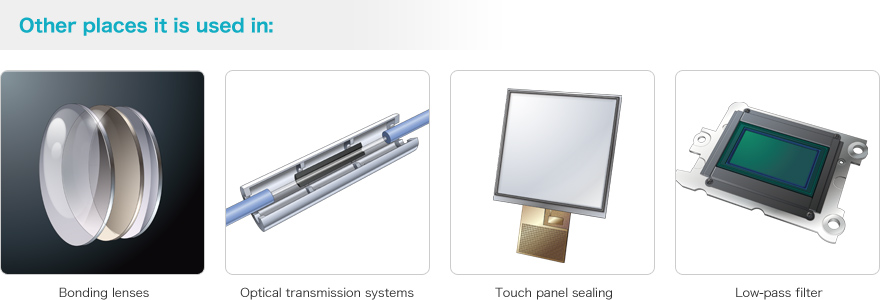

PHOTOBOND is widely used to adhere glass and resins that pass ultraviolet light. We are the leading brand of Japan and popular among many customers. The application of the PHOTOBOND is now extended from glass crafts to optical lenses and electronic components, and we are currently developing products for special uses, coating and temporary joint as well. |

| Product Line-Up |

| ■ PHOTOBOND 300 | For art glass | ■ PHOTOBOND 300K | For optical applications /

standard product |

| ■ PHOTOBOND 029 | For adhesion of different materials /

Low viscosity |

■ PHOTOBOND 150 | For optical applications /

low viscosity |

| ■ PHOTOBOND 200 | For coating and sealing purposes /

aerobic |

■ PHOTOBOND 470

■ PHOTOBOND 475 |

For optical applications /

Light resistance and heat resistance |

| ■ PHOTOBOND 840 | Low Viscosity /

warm water detachable |

|

| Used in such places |

|

|

| Usage Information |

| General instruction (*Please conduct adequate pretest according to your purpose.) |

| 1. Remove dust, oil and dirt |

|

First, clean the work surfaces removing dust, oil and dirt by using solvent, etc.

If you use solvent, wait until the solvent thoroughly evaporated before you started adhering work. |

| 2. Apply PHOTOBOND and adhere |

|

Apply PHOTOBOND to the surface to be adhered, and press the other work surface firmly onto it.

If bubbles appear this time, they would weaken the adhesive power. In that case, rub the work surfaces each other to eliminate the bubbles. The most suitable thickness depends on the adhering conditions. Conduct adequate pretest. |

| 3. Fix work pieces and irradiate ultraviolet light |

|

Use a fixing device to prevent the work pieces from moving.

From the direction more ultraviolet passable, irradiate ultraviolet light vertically and evenly against the work surface. The irradiation time differs depending on adhering conditions. Please conduct adequate pretest. When the adhering surface is large, move the irradiation position gradually, and ensure the entire surface gets the irradiation evenly. |

| 4. Wipe away the runoff PHOTOBOND |

|

The runoff PHOTOBOND does not cure when exposed to ultraviolet as far as there is oxygen.

After the irradiation, wipe it away by suitable solvent (alcohols solvent, petroleum benzine, carbon-hydride cleaner). |

| For the purposes such as coating that cannot block the air, refer to the following information:

1) Place entire work pieces in vacuum. 2) Conduct irradiation in work condition filled with inactive gas such as N2 (nitrogen), CO2 (dry ice). 3) Cover the surface by transparent polyethylene film, etc., and irradiate ultraviolet light through it. Remove the film after the irradiation. |

Price Terms︰ FOB SHENZHEN FOB HONGKONG

Payment Terms︰ TT